CNC Butt Welding, Elbor, Welding Machines

CNC W400 Mono Phase

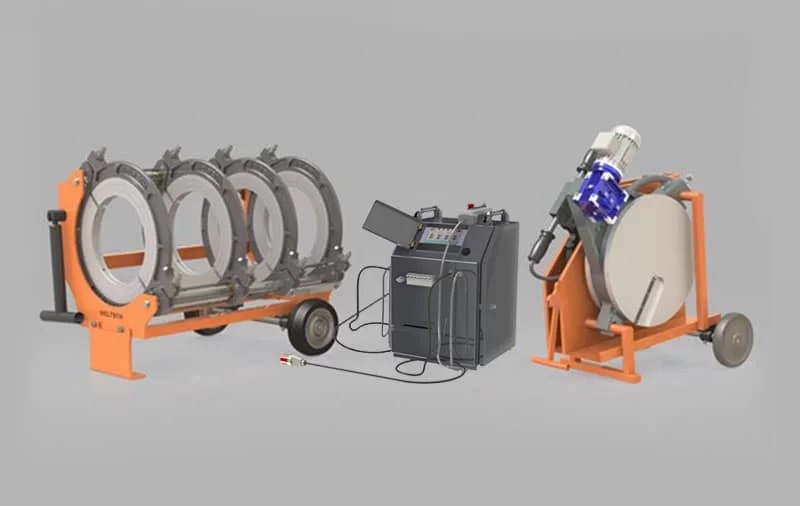

CNC W400 Plastic Pipe Mono Phase Hydraulic Butt Welding Machine

- The machine is for weldings of PE – PP – PVDF pipes and fittings up to 32 Bar Welding sizes are 160 – 180 – 200 – 225 – 250 – 280 – 315 – 400 mm

With the shortest setup time, it provides simple and fast welding operations according to international standards ISO 12176 – 1

With its lightweight nature provides easy handling

Maximum working pressure is 150 Bar

The working environmental temperature is -10 C° ~+40 C°

Main Body

Trimmer

Heater

Control Unit

Housing Box

The main body supports the plastic pipes to be welded with two movable and two fixed clamps on it, and provides fixing and centering. The hydraulic pressure force is applied to the system. With two pistons on the carrier shaft, this force directs the movable clamps back and forth and provides the movement required for the welding process to take place.

It is an element of the butt welding machine that cleans the frontal area of the pipes fixed and centered on the main body with the two rotary blades on the right and left sides and the cutter blades on these blades before the heating process. The rotary motion of the trimmer is provided by the motor and reducer group on it. CNC W400 Butt Welding Machine trimming unit creates burr-free and parallel pipe surfaces.

It is the element of the butt welding machine that prepares the pipe face surfaces, which are brought to the desired roughness by the shaving process, for the joining process by heating them with the heating plate. The temperature adjustment of the heater is made with the digital temperature adjustment thermostat located on the heater plate.

Electric and hydraulic control unit; the electricity required for the operation of the machine, the heater and the razor and the hydraulic pressure to the main machine; The control unit is operated by means of hand control. There are four buttons and a switch on the hand control. The buttons move the movable clamps forward and backward and the switch activates the shaver.

Housing and support box prevent heat loss from the heater. The trimmer protects against external influences (impact, water, etc.) by supporting the heater.

Technical Specifications

Content

Packaging Details

| Technical Specifications |

| Welding Range | Ø 160 mm – Ø 400 mm

(Ø160 mm, Ø180 mm, Ø200 mm, Ø225 mm, Ø250 mm, Ø280 mm, Ø315 mm, Ø355 mm, Ø400 mm) |

| Pipe Types to Weld | PE – PP – PVDF |

| Pipe Max. Pressure | PN32 |

| Heater Electric Power | 380 V – 4,5 kW |

| Trimmer Electric Power | 380 V – 1,1 kW |

| Power of Hydraulic Unit | 380 V – 0,75 kW |

| Electric System | Triple Phase |

| Total Electricity Consumption | 7,35 kW |

| Operating Pressure | 150 Bar |

| Required Generator Power | 12 kVA |

| Working Temperature | (-40 C° ~ + 40 C°) |

| Hydraulic Oil | Hydraulic 46 / 4 lt |

| Content |

| User Manual | 1 ad/ pcs |

| Main Body | 1 ad/ pcs |

| Trimmer | 1 ad/ pcs |

| Heater | 1 ad/ pcs |

| Protective Casing | 1 ad/ pcs |

| Stuffer | 32 ad/ pcs |

| Tool Bag | 1 ad / pcs |

| Packaging Details |

| Type of Package | Wooden Case |

| Number of Packages | 1 paket / pack |

| Dimensions | 1,26 x 1,30 x 1,21 |

| Total Volume | 1,98 m3 |

| Total Net Weight | 364 kg |

| Total Gross Weight | 428 kg |